Overview

Drone-based inspections are rapidly taking over the utility industry and for good reason. At Colorado Aerial Imaging, we strive to provide solutions that are more useful, accurate, and safe than the traditional methods employed by utilities across the nation. Keep reading to find out what we can do for you!

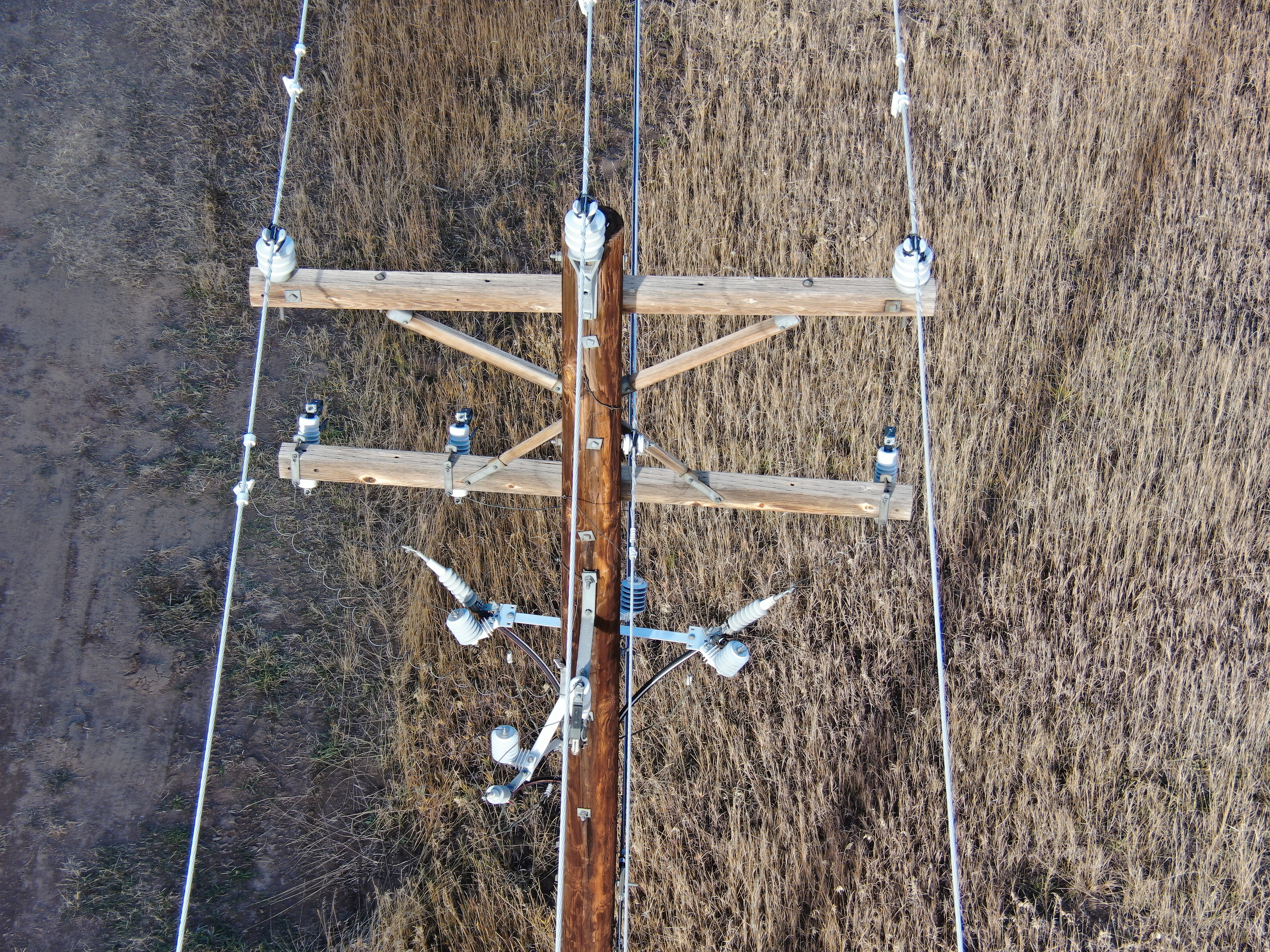

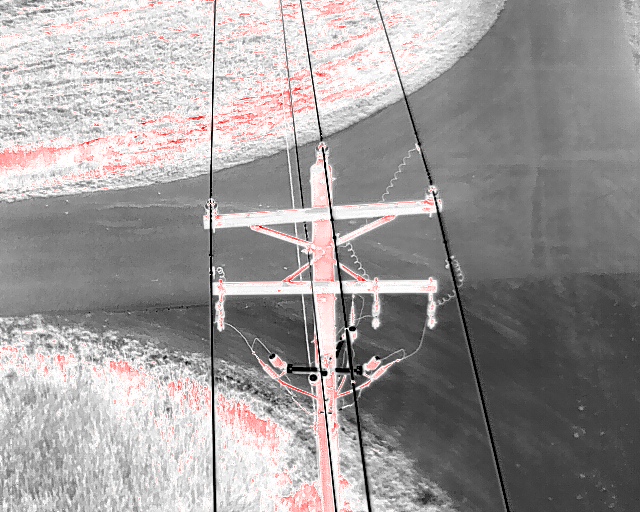

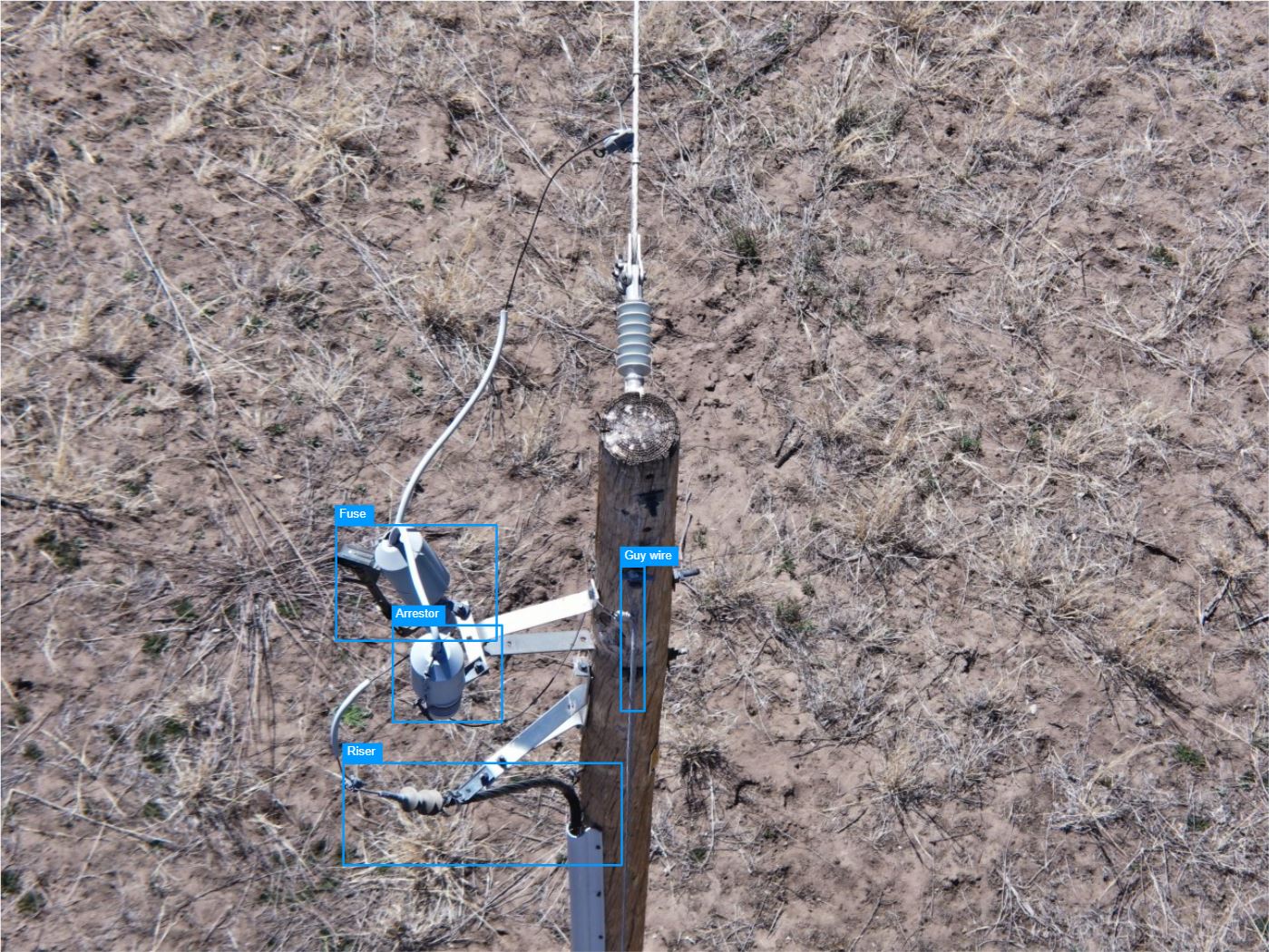

Visual(RGB) Inspection

Efficiency meets precision with our high resolution Visual Inspections. Our UAS crews capture detailed images from angles not easily accessible through traditional methods. Gain a comprehensive view of your structures and hardware, while identifying potential issues. Our imagery goes beyond ground inspections, ensuring a thorough assessment for proactive maintenance. Elevate your visual inspections, safeguarding your assets with practical insights from above.

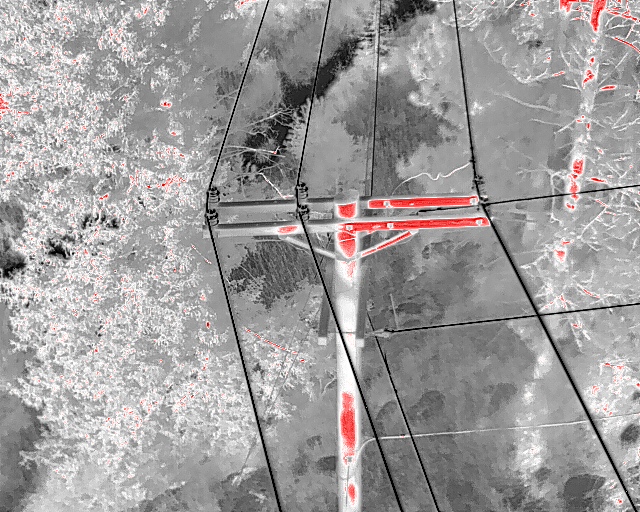

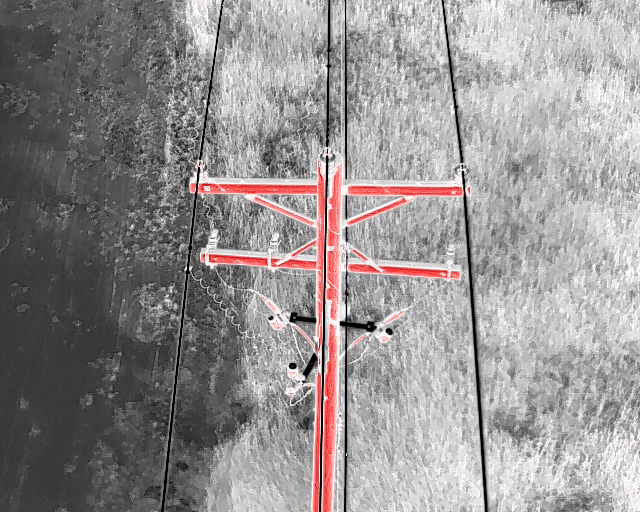

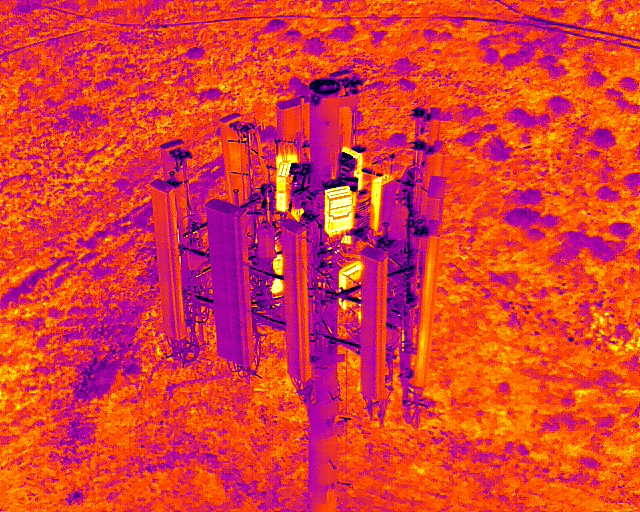

Thermal Inspection

Uncover the invisible with our Thermal Imagery Inspections. In the realm of electrical structures, not all issues are visible to standard cameras. Thermal imaging helps to provide a comprehensive understanding, detecting potential problems before they escalate. Our thermal inspections have revealed hidden issues like tracking, hot insulators, and transformers that can be invisible to the naked eye. For more information on thermal and how it integrates with the visual inspections, give us a call!

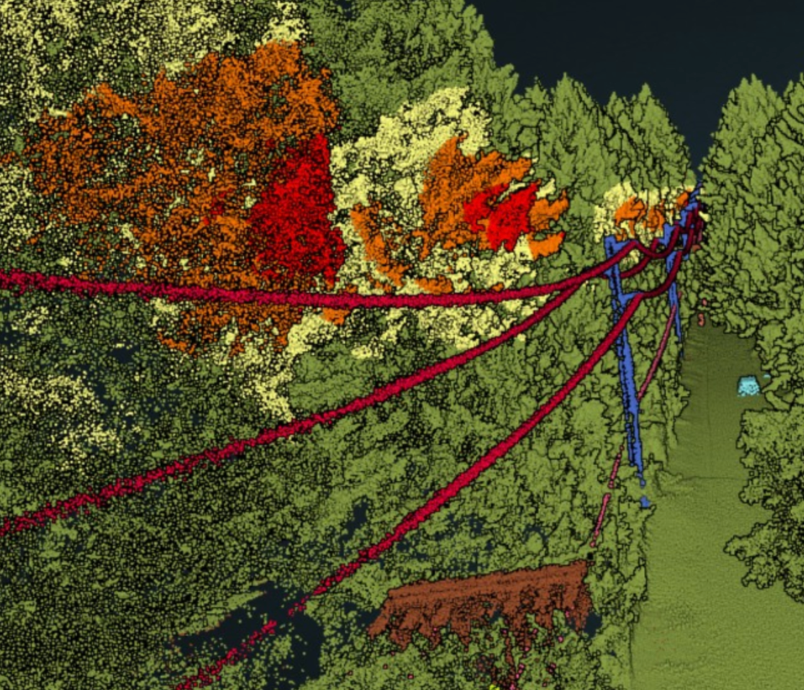

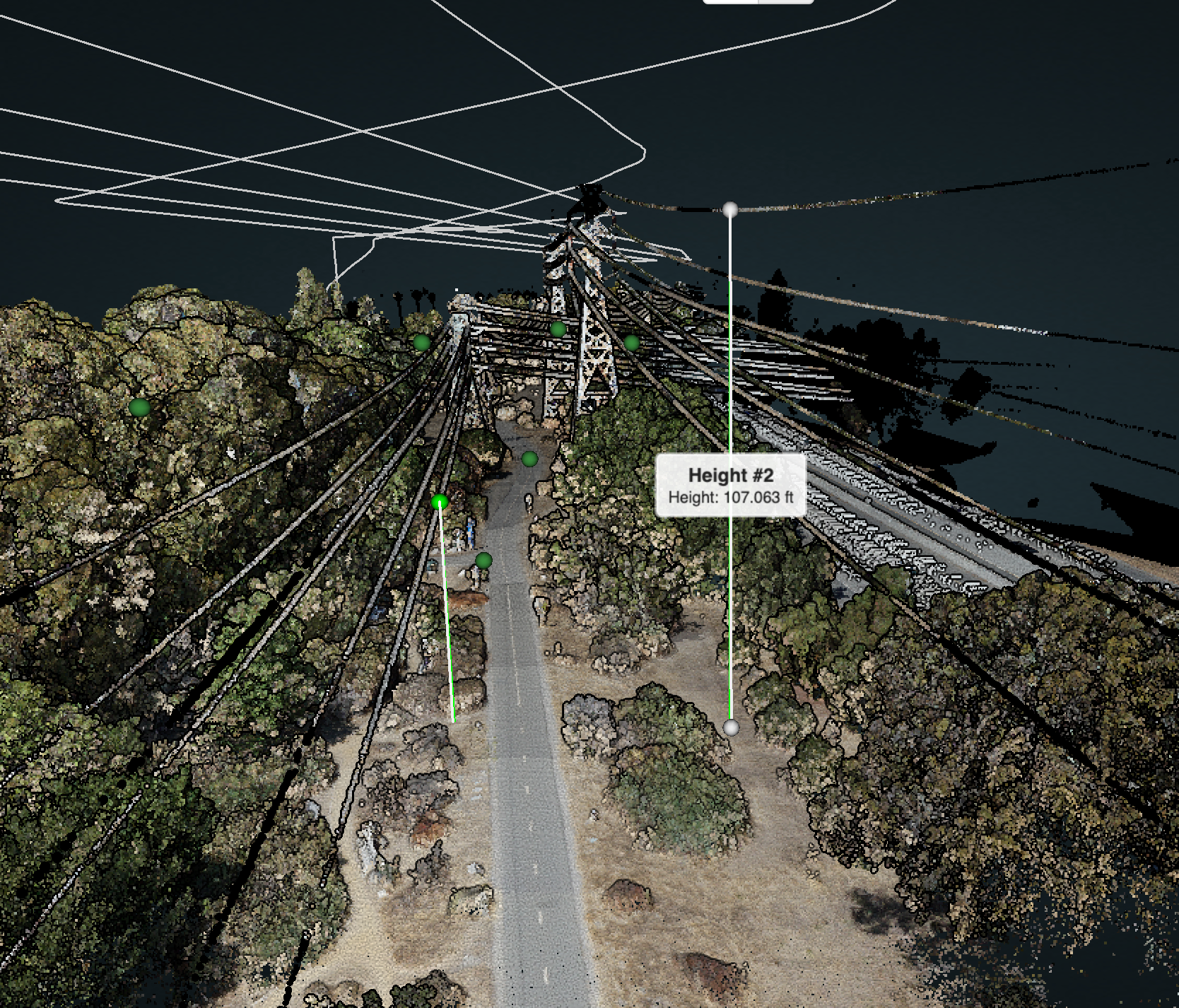

LiDAR Scans

LiDAR scans combine detail and precision into a 3D space. We can deliver high fidelity scans of any area and the assets that exist within it. Whether you’re measuring line sag, checking for NESC violations, or identifying encroaching vegetation, LiDAR data ensures you have what you need to get the job done. Experience unparalleled accuracy with Colorado Aerial’s LiDAR technology – where every dimension matters.

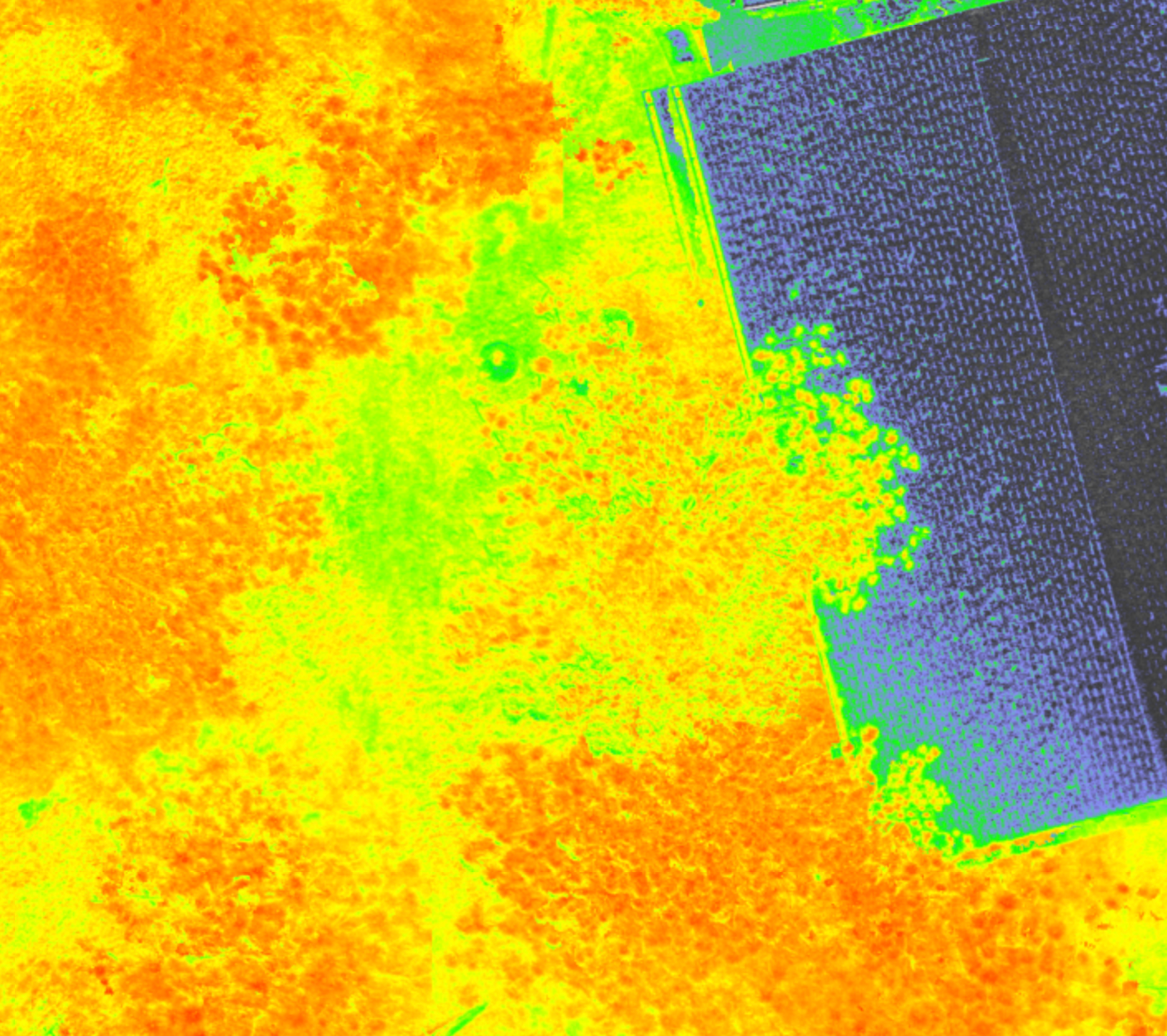

Right of Way Multispectral Analysis

Uncover the health of the foliage surrounding your assets with our Multispectral Analysis. Utilizing an array of cameras capturing diverse wavelengths of non-visible light, we can measure the reflectivity of trees and other vegetation. By layering these images, we discern plant health, identifying potential threats like dead or dying trees that pose a risk to power lines. Drone based Multispectral sensors allow you to canvas right-of-ways, proactively spotting and addressing potential issues. Colorado Aerial’s Multispectral Analysis is yet another way you can gain a comprehensive understanding of you system and the environment around it.

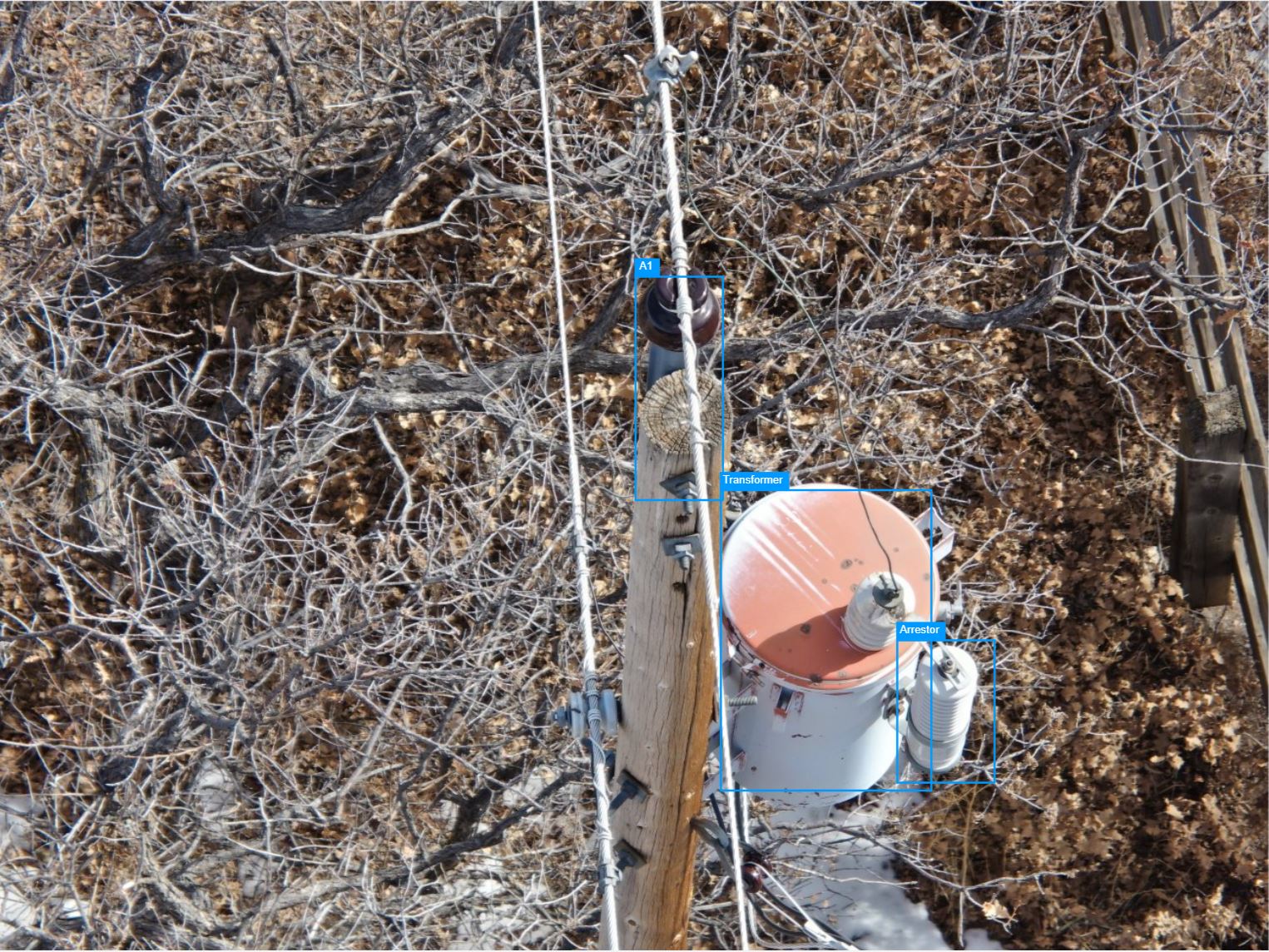

Asset Management

Optimize your operations with our Asset Management solutions. Our tailored inspections provide a detailed inventory of hardware on your poles, offering precise information on type and location. Seamlessly integrated with our visual inspections, Asset Management is customizable to target your critical infrastructure. Efficiently track, replace, and maintain hardware with unparalleled accuracy, elevating your management strategy to new heights.

QA/QC Checks

Our UAS systems capture images with incredible detail. A 23x optical zoom lens allows our crews to capture the smallest pieces of hardware without having to get too close. Often times the photos appear as if they where taken from a few feet away, when in reality the aircraft is significantly farther from the pole. While capturing this level of detail may require extra time, the precision is invaluable for utilities ensuring their structures meet specifications. Give us a call to find out how we combine meticulous detail with uncompromising quality assurance!

Overview

Drone-based inspections are rapidly taking over the utility industry and for good reason. At Colorado Aerial Imaging, we strive to provide solutions that are more useful, accurate, and safe than the traditional methods employed by utilities across the nation. Keep reading to find out what we can do for you!

Visual(RGB) Inspection

Efficiency meets precision with our high resolution Visual Inspections. Our UAS crews capture detailed images from angles not easily accessible through traditional methods. Gain a comprehensive view of your structures and hardware, while identifying potential issues. Our imagery goes beyond ground inspections, ensuring a thorough assessment for proactive maintenance. Elevate your visual inspections, safeguarding your assets with practical insights from above.

Thermal Inspection

Uncover the invisible with our Thermal Imagery Inspections. In the realm of electrical structures, not all issues are visible to standard cameras. Thermal imaging helps to provide a comprehensive understanding, detecting potential problems before they escalate. Our thermal inspections have revealed hidden issues like tracking, hot insulators, and transformers that can be invisible to the naked eye. For more information on thermal and how it integrates with the visual inspections, give us a call!

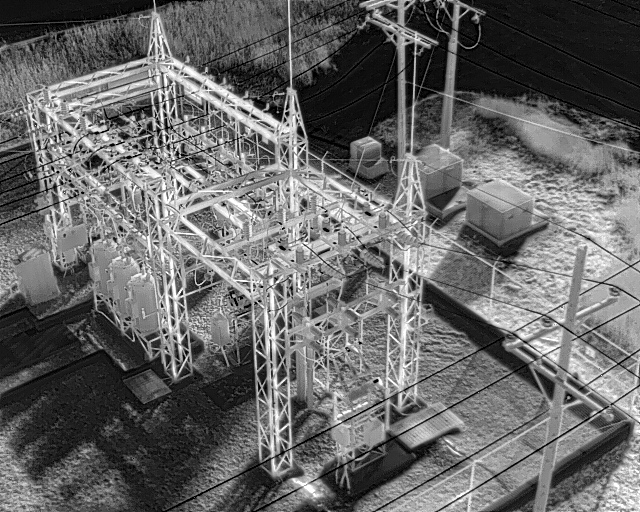

LiDAR Scans

LiDAR scans combine detail and precision into a 3D space. We can deliver high fidelity scans of any area and the assets that exist within it. Whether you’re measuring line sag, checking for NESC violations, or identifying encroaching vegetation, LiDAR data ensures you have what you need to get the job done. Experience unparalleled accuracy with Colorado Aerial’s LiDAR technology – where every dimension matters.

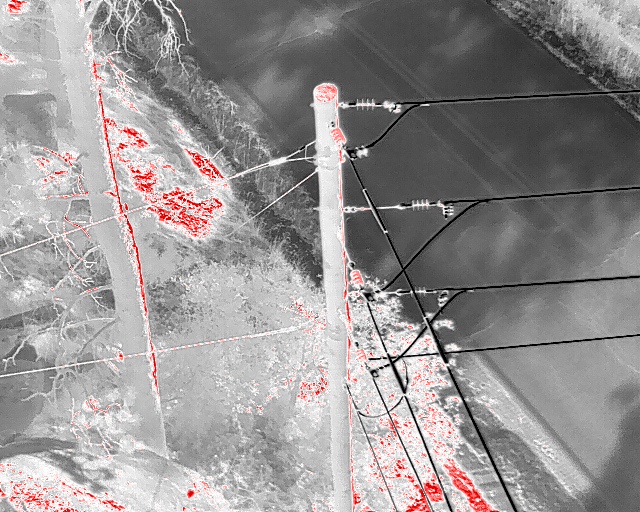

Right of Way Multispectral Analysis

Uncover the health of the foliage surrounding your assets with our Multispectral Analysis. Utilizing an array of cameras capturing diverse wavelengths of non-visible light, we can measure the reflectivity of trees and other vegetation. By layering these images, we discern plant health, identifying potential threats like dead or dying trees that pose a risk to power lines. Drone based Multispectral sensors allow you to canvas right-of-ways, proactively spotting and addressing potential issues. Colorado Aerial’s Multispectral Analysis is yet another way you can gain a comprehensive understanding of you system and the environment around it.

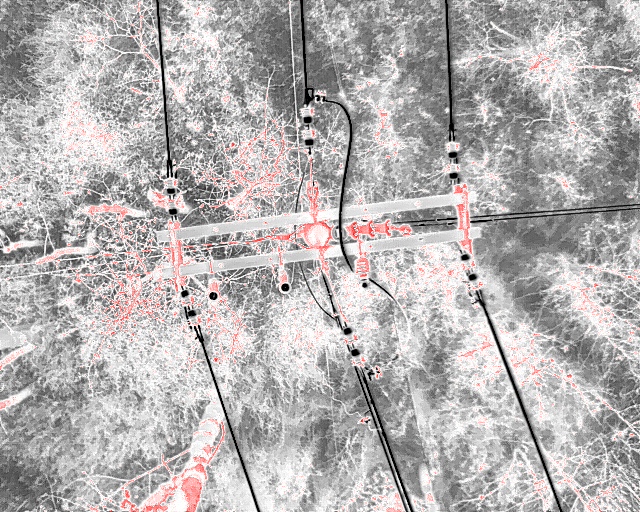

Asset Management

Optimize your operations with our Asset Management solutions. Our tailored inspections provide a detailed inventory of hardware on your poles, offering precise information on type and location. Seamlessly integrated with our visual inspections, Asset Management is customizable to target your critical infrastructure. Efficiently track, replace, and maintain hardware with unparalleled accuracy, elevating your management strategy to new heights.

QA/QC Checks

Our UAS systems capture images with incredible detail. A 23x optical zoom lens allows our crews to capture the smallest pieces of hardware without having to get too close. Often times the photos appear as if they where taken from a few feet away, when in reality the aircraft is significantly farther from the pole. While capturing this level of detail may require extra time, the precision is invaluable for utilities ensuring their structures meet specifications. Give us a call to find out how we combine meticulous detail with uncompromising quality assurance!