Real World Examples

You may be wondering what types of problems an Aerial Inspection can uncover. Below are a few examples of real problems found in the field that would have been difficult to detect without an Aerial Inspection. Each example required immediate maintenance by our customers.

Tip: Hover cursor over images to zoom.

Faults Not Visible From the Ground

Perhaps the biggest advantage to an aerial inspection is the speed in which the top of any given structure can be viewed. The top of the structure has the most exposure to the elements and is at a higher risk for rot. Lineman would need to physically climb the pole, use a bucket truck, or be in a helicopter to see damage from above. The images below depict the same pole from both the drone and from the ground looking up. It is a perfect example of how much more effective an aerial inspection can be versus a standard line patrol.

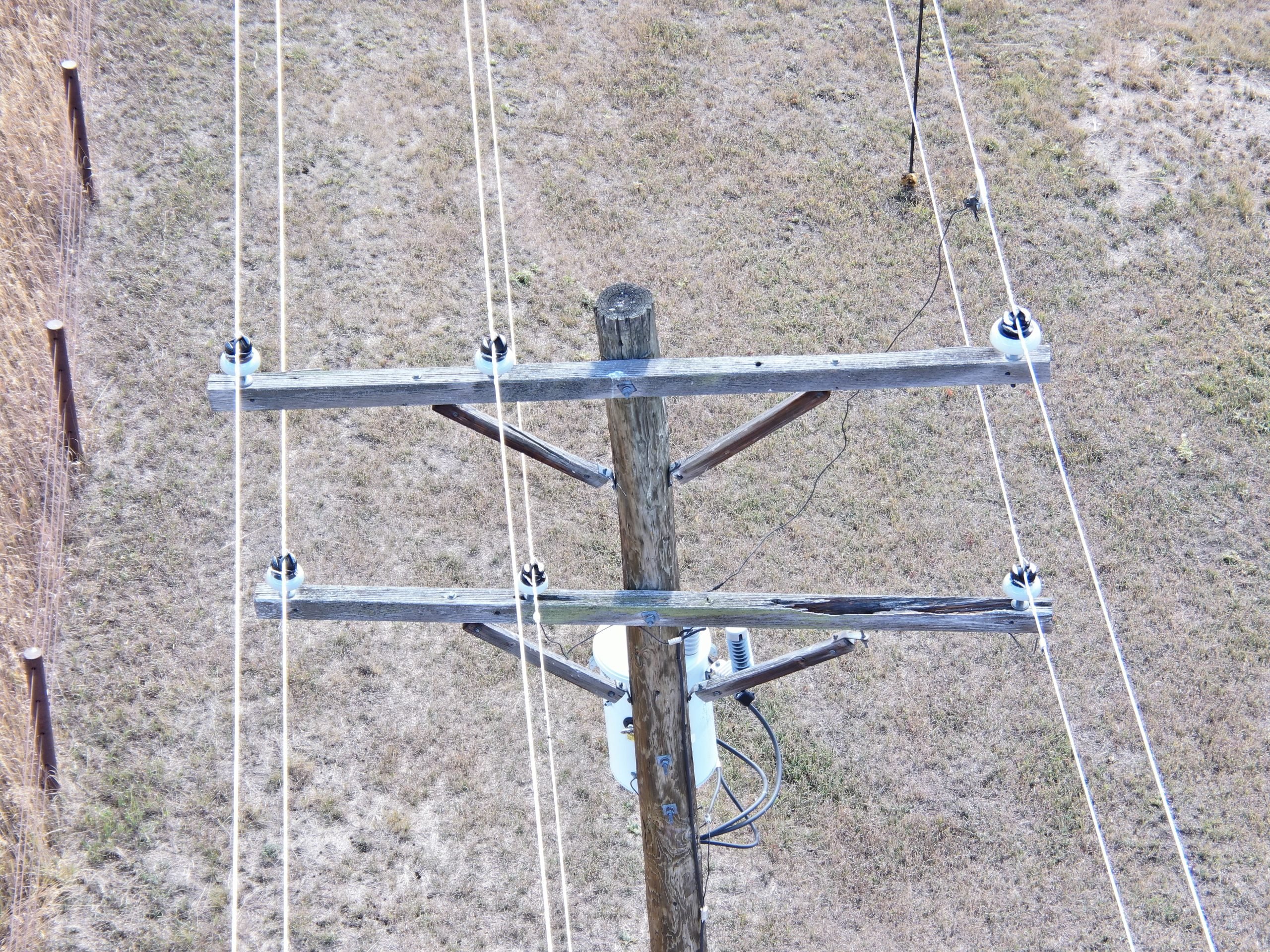

Cross-arm Rot: Drone View

As evidenced by the photo, this pole has a serious case of wood rotting from the top. Both the right and middle insulators on the bottom cross-arm are in danger of becoming detached. The rot is so bad on the right side that it looks like it goes through the entire cross-arm.

Cross-arm Rot: Ground View

When looking at this pole from below, it is surprising that the rot on the right side is not visible. The walking line patrol performed prior to our aerial inspection did not catch the rot, and this picture shows why. Issues on the top of a pole are simply not easy to see from the ground.

Thermal Fault Detection

The ability to take a thermal and RGB photo simultaneously allows our lineman inspectors to quickly compare issues to determine their severity. Below are two photos of the same pole, taken within 1 second of each other. The fault shown below was a faulty secondary plug that required replacement of the entire transformer.

Thermal Image: Red=Hot

The thermal image clearly depicts the plug on the right side of the transformer as hotter than it’s surroundings. This is usually the first hint that there could be a problem. The transformer itself also appears hotter than the other componentry.

High Resolution RGB Image

Although the RGB images have fantastic clarity, it doesn’t help much in this scenario. There is little to no visible damage visible to the naked eye in this image. No inspection will catch 100% of the issues on a section of line, but the thermal camera helps us get closer.